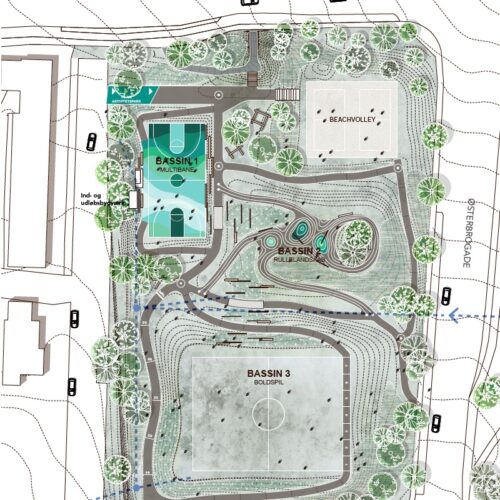

City parks with SUDS technology and fitness equipment Parks around the world are being transformed into multifunctional areas that serve both as green spaces and as local water collection and...

Read MoreEnvironment

At NOORD, we take responsibility and strive to make a difference for the environment. On this page you can read more about our approach and lean about NOORD.

Environment

At NOORD, we take responsibility and strive to make a difference for the environment. On this page you can read more about our approach and lean about NOORD.

Our general approach

At NOORD, one of our primary focuses is to operate a sustainable and healthy business with a large focus on the environment. As part of our development, we have obtained the Scandinavian ecolabel, Nordic Swan Ecolabel, for all our fitness equipment in the “Sprouts series” and achieved the highest environmental certification of A+ from the Swedish SundaHus. We have also conducted a Life Cycle Assessment (LCA) of our production processes in collaboration with the Technical University of Denmark to calculate the carbon footprint of all our products.

Scandinavian design, scandinavian production

At NOORD, we believe that protecting the environment is not just a responsibility, but also a source of pride. As a Danish company, we value our local roots and are committed to keeping production close to home. By doing so, we can minimize the transportation of our sport equipment in the production phase, reducing CO2 emissions and our environmental impact.

However, our environmental commitment goes beyond logistics. We believe that doing business sustainably means taking responsibility for every step of the production process. That’s why we’re proud to say that all of our sport equipment is produced exclusively from 100% recyclable steel.

Recycling steel is not only environmentally friendly, but it’s also energy-efficient. This approach requires less energy and generates fewer CO2 emissions compared to producing new steel. By using 100% recyclable steel, we are reducing our carbon footprint while also contributing to a circular economy.

With Danish production, our customers can also be assured that strict environmental and production requirements are applied. In Denmark, we are subject to stringent environmental regulations, ensuring that at NOORD, we are compelled to deliver products of the highest quality to meet all applicable legal requirements. This includes adhering to high standards for waste management and handling of hazardous chemicals, resulting in reduced environmental impact.

Life Cycle Assessment (LCA) made by Technical University of Denmark

To make the most environmentally responsible decisions in our production, we have commissioned a Life Cycle Assessment (LCA) from DTU (Technical University of Denmark). At NOORD, we generally adopt a data-driven approach to environmental sustainability, providing us with the best possible foundation for making the right choices. The LCA shed light on, among other things, the most environmentally friendly type of steel to use in production. The results were clear: the most environmentally friendly steel type for manufacturing our products is 100% recyclable black steel.

In fact, the calculations showed that producing our outdoor fitness equipment in stainless steel would result in emitting over double the amount of CO2, while also being more detrimental to health.

Surface treatment and powder coating

Another important parameter in production is the way we protect against rust and perform surface treatments. At NOORD, we do everything we can to maintain a high level of quality to meet our customers’ expectations. Therefore, we use an environmentally friendly water-based process called E-coat to protect our products against rust. E-coating not only ensures that our products remain rust-free internally and externally but also eliminates the risk of hazardous emissions and reduces the amount of hazardous waste generated during the process.

E-coating is an extremely robust protection method, providing high durability and resistance to wear and scratches, making the products easy to clean and maintain. E-coating is often recognized from the automotive industry, where the majority of cars undergo rust protection using the same method.

In practical terms, our rust protection process involves immersing the products in a tank of E-coat at a temperature of approximately 33°C. Subsequently, the equipment are cured in an oven at 160°C for about 15 minutes.

Another option could have been to use the commonly used galvanization process. However, we deliberately chose NOT to use galvanization/hot-dip galvanization for our products, as it involves immersing the equipment in liquid zinc at a temperature of approximately 460°C.

In addition to rust protection, our products undergo a surface treatment that protects them against degradation and corrosion, thereby extending their lifespan and minimizing resource consumption. At NOORD, we feel obligated to minimize our environmental impact, and one of the reasons we have chosen powder coating as our preferred surface treatment is because it is an environmentally friendly solution compared to solvent-based alternatives. Powder coatings do not contain solvents and therefore only emit a minimal amount of volatile organic compounds (VOCs) into the atmosphere. After curing, powder coatings release virtually no VOCs during their lifespan, making them a sustainable choice for us and our customers.

At NOORD, we are constantly moving forward and working every day to optimize and find new innovative ways to reduce our environmental impact.

See our range of products

NOORD presents a wide and solid product range of outdoor fitness equipment and OCR/obstacle courses. All equipment with the same good properties, where functionality and aesthetics are paramount. Our minimalistic Danish designed and produced equipment is produced with consideration for the environment and with a minimal carbon footprint. We are proud to be able to maintain all production in Denmark for the benefit of the environment.

See our full range of outdoor training equipment, which we call “Spirerne” – or “The Sprouts” in English. NOORD’s training equipment is aimed at both experienced and inexperienced users.

NOORD has developed equipment for an obstacle course race that can be used as a fun and challenging way to train in order to increase strength, endurance, balance and coordination.

New Forensic Psychiatry at Sankt Hans in Roskilde

New Forensic Psychiatry at Sankt Hans in Roskilde An award-winning building was ready for inauguration in 2022. The Danish health building of the year 2022 was the forensic psychiatry at...

Read MoreRoof terraces – Inspiration for active rooftops

Roof terraces are increasingly being used as active spaces Roof terraces are more and more often used for purposes such as relaxation, barbecue evenings and much more. At NOORD Outdoor...

Read MoreElegant fitness park in Roskilde, Denmark

Elegant fitness park in Roskilde, Denmark NOORD Outdoor Fitness has delivered a fitness park with outdoor fitness equipment and wetpour rubber surfacing to the municipality of Roskilde in Denmark. The...

Read MoreContact Us

If you are looking for a professional business partner, you have come to the right place. We take pride in providing an extraordinarily good service. Our team has many years of experience and we are happy to be available to you when you need advice or sparring for your project.